Description

(1) – one – ITALFORNI S.R.L. 349’ long x 9’ 4” wide Double Deck Roller Hearth Kiln for firing ceramic products, with 10’ wide x 10’ long Roller Feeder and 10’ wide x 19’ long roller unloader; 49 sections, 12’ long x 2.165 diameter ceramic rollers, 209 installed IF55: 55,000 KCAL/H natural gas burners. Kiln set up with 31 modulating gas zones and 2 modulating air zones for flash & rapid cooling zones. Includes blower fans with duct work system for hot & cool air zone circulation. Electronic automated kiln controls with disconnects and motor starters. Type: OK 106.33/2850/B; S/N 06/338; Date of Mfr. 2006.

*A 10-Page kiln manufacturer technical sheet is available describing the original equipment supplied at the time of delivery and installation. EarthWORKS assumes this list is accurate. Any field revisions that EarthWORKS is not aware of is included and accepted with the “as is” sale.

Used Equipment………REDUCED Selling Price $225,000.00

Disassembly and truck loading costs to the buyers’ account. Assistance with choosing and managing local vendors for this task is available upon request.

Condition: Generally good. In use for 5 years, 2007 thru 2012.

This kiln was purchased new in 2006 and installed inside the US Tile manufacturing facility in Ione, California. They set up two roof tile production lines. It was first fired in 2007 and in use for 5 years. It has remained fully assembled and stored indoors as seen in the provided photos.

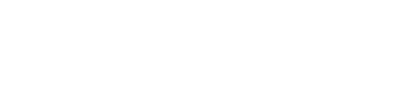

Plant Controls: The selection of electrical components and the construction of the cabinets was done according to American UL standards. The power-section was built with UL-approved components from Rockwell. As the PLC, an Allen-Bradley SLC500 with decentralized peripherals on Devicenet was used.

The equipment with all related parts and accessories will be sold “as is–where is”. Costs for disassembly, truck loading, and transport will be to the buyer’s account. Assistance with choosing and managing local vendors for this task is available upon request.